DesignSmart

Engineering Made Easy

An end to end web-based engineering software that transformed Alumi's manufacturing operations.

Need for modern and easy to use technology

In late 2023, Alumi engaged Devinci. Following an initial workshop, Devinci swiftly recognised the need for a web-based quotation and engineering software. This system was crucial not only for accommodating the diverse and dynamic needs of Alumi's projects but also for supporting the company's business continuity plan. To achieve this transformation, Devinci developed a platform designed to solve complex engineering problems and integrate seamlessly with Alumi’s ERP system to meet the business’s needs.

Our approach

Initial Workshops and Interviews

- Conducted multiple workshops with key stakeholders from Alumi.

- Gathered insights on business needs, goals, and target audience.

- Identified key features and functionalities required for the project.

- Established a project timeline and milestones.

Design Phase: Focus on user experience

- Conducted user research to understand the pain points of the end-users.

- Created personas to represent different user types.

- Developed user journey maps to visualise the user experience.

- Designed wireframes to outline the structure and layout of the application.

- Developed high-fidelity UI designs incorporating branding elements and visual guidelines.

- Conducted design reviews and iterations based on feedback from Alumi stakeholders.

Prototyping

- Developed clickable prototypes based on the finalised UX/UI designs.

- Ensured prototypes were functional enough to simulate real user interactions.

- Presented prototypes to Alumi stakeholders for initial feedback.

- Refined prototypes based on stakeholder feedback to ensure alignment with business goals.

Implementation

- Followed agile methodology with iterative development cycles (sprints).

- Conducted regular stand-up meetings and sprint reviews to track progress.

- Performed continuous integration and testing to ensure quality and functionality. Collaborated with Alumi stakeholders for ongoing feedback and adjustments.

- Conducted user acceptance testing (UAT) to ensure the product met all requirements.

- Deployed the final product in a production environment.

- Provided post-launch support and monitoring to address any issues and gather feedback for future improvements.

The solution

Devinci collaborated with Alumi to develop DesignSmart, a module-based integrated platform that manages the entire workflow for engineers, from quotation to the issuance of engineering orders. This comprehensive solution includes the following modules:

- Product Catalog Definition: Allows users to define product ranges and configurations.

- Bill of Material Definition: Establishes a hierarchical material structure for each product, including unit cost and sales price for both quotation and cost analysis purposes.

- Automation Rules: Users can set rules and constraints for automatic product construction.

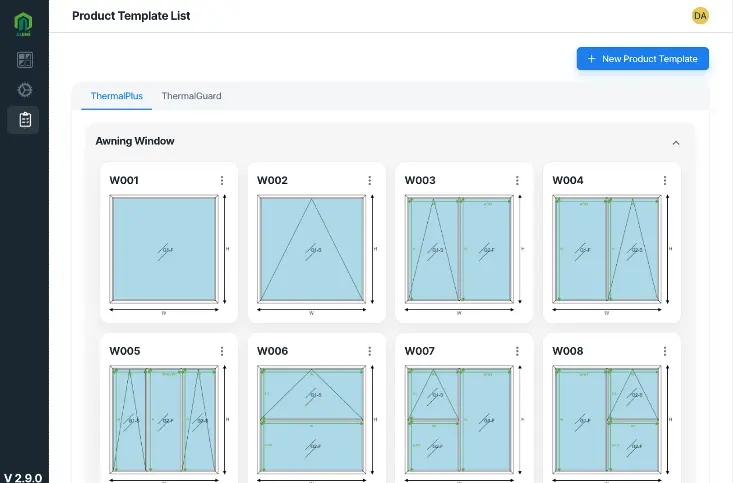

- Product Templates: Users can create product templates to maximise design efficiency.

This module enables users to define the project brief, including the creation of project-specific products. The user interface is designed to minimise user input, thereby maximising design and engineering efficiency. Within the project view, users gain a comprehensive overview of project requirements and can navigate easily to specific products for detailed examination. Additionally, project-level controls allow for the bulk application of settings across all products in a given project.

The quotation process is fully automated. Once the project products are defined, users simply click a button to automate the entire quotation process. The system automatically generates all necessary documents to support the sales team, utilizing predefined unit prices, rules, and constraints. The integration of a smart pricing engine eliminates the need for engineers to manually calculate costs in spreadsheets.

Historically, engineers manually specified each product's dimensions, material selection, glazing details, façade, and cladding details. Now, these specifications are calculated automatically, including the automation of all production order documents - often comprising more than ten separate documents. Certain documents, like the glazing sheet, can be directly uploaded to the vendor's ordering system to automate glass orders.

Alumi employs a modern ERP system that supports interoperability via RESTful APIs. The DesignSmart platform leverages these APIs to directly create material pick orders and transfer orders within the ERP system, ensuring that inventory and production operations are consistently synchronised and share the same source of truth. When a production order has been issued, the required materials are automatically reserved in the inventory system, and once production is complete, these materials are deducted from the inventory.

100% Efficiency Boost

DesignSmart has eliminated the need for manual calculations and repetitive tasks. Because all the engineering rules and constraints are predefined, it frees users from tedious tasks, allowing them to focus on more creative work.

50% Reduction

Training Time

Because best practices and workflows are seamlessly integrated into DesignSmart in an easy-to-understand manner, it significantly shortens the training time for new team members.

10% Reduction

Production Cost

The substantial reduction in the potential for errors within DesignSmart is primarily due to the system's capability to automate the calculations required in the engineering process. As a result, the production team experiences fewer interruptions and less need for rework, leading to a more reliable production flow.

0 Licensing Cost

No more expensive annual subscription fee for desktop based applications.